Large injection molding machines are essential equipment in the industrial manufacturing industry. They help manufacturers produce high-quality products in large quantities quickly and efficiently. However, these machines are expensive and require specialized training to operate correctly. Given their size, they also occupy a lot of space, making it challenging to move around when needed. This article will examine facts about large injection molding machines you must know before purchasing.

Large Injection Molding Machines are crucial for making great products

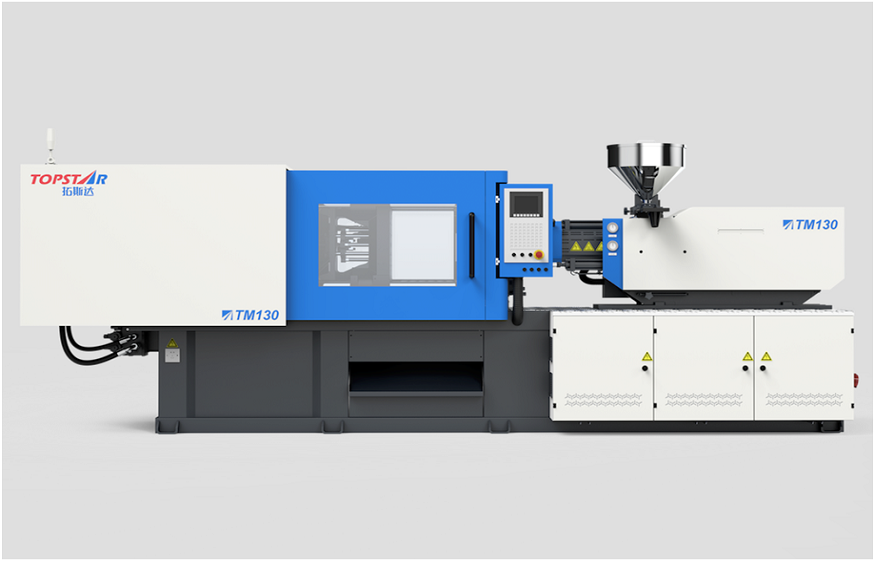

A large injection molding machine is a machine suitable for producing plastic parts. They are essential to manufacturing quality products and are ideal for many industries.

In the automotive industry, large injection molding machines create plastic parts like car seats, dashboards, and door panels. Aerospace manufacturing produces airplane seats, airbag components, and other items, such as landing gear struts or control cables that withstand extreme temperatures. At the same time, being subjected to high-stress loads over long periods.

The construction industry relies heavily on these types of machines because they allow for mass production at low costs for materials needed during construction projects such as concrete formwork systems – which consist mainly of wood fibers reinforced by steel bars – allowing builders access easy access points without worrying about damaging expensive materials like glass panes or aluminum window frames etcetera.

Advantages of Using Large Injection Molding Machines

The advantages of using large injection molding machines are numerous. The first and perhaps most obvious benefit is that they can make large parts. This is particularly useful if you’re making a part that would be difficult or impossible to do with small injection molding machines or if you need to produce many similar parts simultaneously.

Mass production runs are also easier to manage when using these machines as they feature an automatic loading system. It is possible to keep everything organized and neat without any human intervention. These machines also handle other tasks automatically when changing molds or cleaning up excess material from a previous batch. This frees workers’ time to focus on quality control checks!

Large injection molding machines are suitable for producing heavy plastic parts!

They are suitable for the mass production of large plastic parts. The size of a large injection molding machine is in kilograms, which refers to the weight of the metal shell and core components and their dimensions. A machine with a capacity of 10 kg can produce large products such as car bumpers or truck fenders.

Large plastic products are often produced using this type of machinery because it allows companies to make large quantities quickly and efficiently–an important factor when dealing with mass production needs such as those found in automobile manufacturing plants or construction sites where workers need access to tools soon while working on site.

Has played a massive role in the manufacturing industry

They have changed the way we live, work, and play. They have also changed our way of thinking and looking at things. Large Injection Molding Machines are used to produce large numbers of products at one time, which makes them very efficient compared to other types of machines, such as small injection molding machines that produce only small quantities per hour because they need time to cool down before starting another cycle again after they have made every few parts means that if you want more than one piece per hour, larger machines will be better suited for your needs rather than smaller ones, which may not be able to keep up with demand if there’s high demand for certain products like car seats or televisions, etcetera.”

Large injection molding machines have become a necessity in today’s world

Industries use them to manufacture products that require large volumes and heavy-duty usage. The manufacturing sector is one of the biggest beneficiaries of these machines as they use them for making products ranging from car parts to household appliances.

The advantages of using large injection molding machines include the following:

They can produce large quantities simultaneously, reducing production costs significantly.

These machines can make large molds, meaning different parts or components do not require multiple molds. On the contrary, you only need to use a large area of decay once, which can save you the trouble of spending the extra money to manufacture new molds every time the demand for your product/service increases. This is easier for businesses as they will not have any maintenance cost issues either!